La finition de surface est une étape cruciale dans la fabrication de dispositifs médicaux, en particulier pouralliages de titane utilisé dans les implants et les outils chirurgicaux comme forceps,scalpels,articulations artificielles du genou, et stents vasculairesélectropolissage etpolissage vibratoire mécanique, deux techniques automatisées de pointe, axées sur leurdistinctions techniques,implications financières

Les alliages de titane (par exemple, Ti-6Al-4V) sont privilégiés pour leurrapport résistance/poids élevé rapport,résistance à la corrosion, et biocompatibilitéCependant, des défauts de surface tels que des micro-rayures ou une contamination peuvent entraîner une inflammation ou une défaillance de l’implant.Polissage automatisé

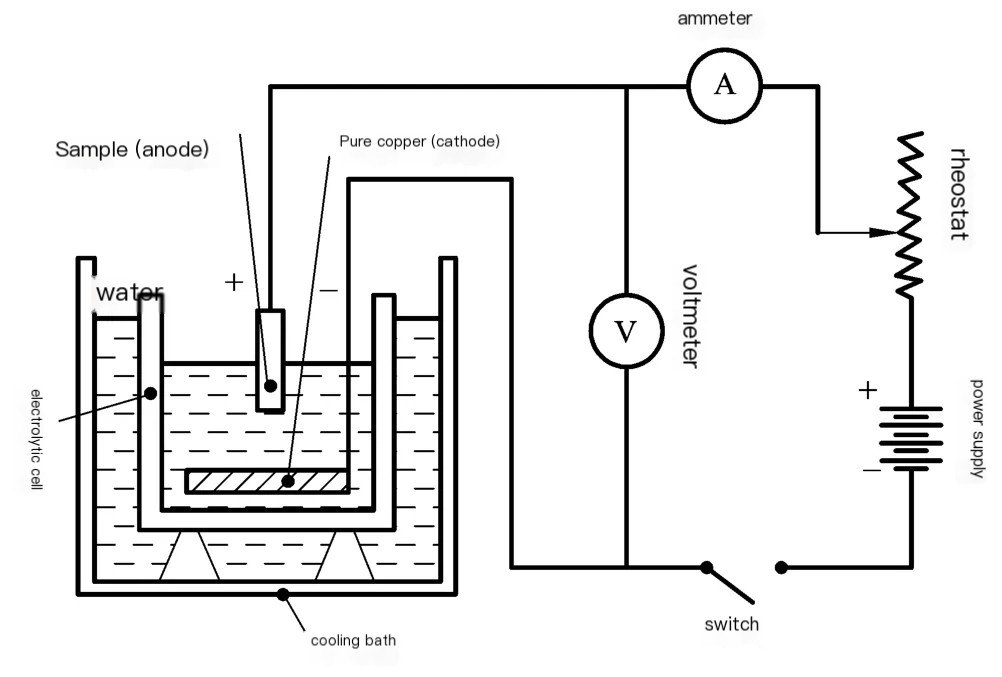

électropolissage est unprocédé électrochimique où la pièce en titane agit comme unanode immergé dans un électrolyte spécialisé (par exemple, des solutions acides). Uncourant continu dissout sélectivement les micro-saillies de surface, obtenant ainsi unefinition miroir avec une rugosité (Ra) aussi faible que0,1–0,4 μm

l Qualité de surface supérieure: Élimine les micro-fissures et les bavures, idéal pourgéométries complexes (par exemple,stents vasculaires)

l Résistance à la corrosion améliorée

l Traitement par lots:Haut débit pour la production de masse

l Coût initial élevé: Nécessiteéquipement coûteux (redresseurs, réservoirs à température contrôlée)

l Gestion des déchets chimiques

l Flexibilité géométrique limitée: Moins efficace pour les canaux internes ou les parois ultra-minces

Polissage vibratoire mécanique utilisationsmédias abrasifsaction de culbute broie physiquement la surface du titane, atteignant des valeurs Ra de0,2–0,8 μm

l :Machines de base et supports réutilisables

l Flexibilité: Gère des pièces complexes commearticulations artificielles du genou

l Aucun risque chimique

l Incohérences de surface

l Travail intensif:Nécessite des changements de support fréquents et une inspection manuelle

l Enlèvement de matière:Peut modifier les dimensions critiques des dispositifs à parois minces

| Paramètre | électropolissage | Polissage vibratoire mécanique |

| Rugosité de surface (Ra) | 0,1–0,4 μm | 0,2–0,8 μm |

| Complexité géométrique | Limité | Haut |

| 5–20 μm/min | 2–10 μm/min | |

| Impact environnemental | Déchets chimiques | Émissions de poussières/particules |

| 50 000–200 000 | 10 000–50 000 | |

l électropolissage:Les articles coûteux comprennentredresseurs (30k–80k) etépurateurs de fumées (25k–50 000)

l Polissage mécanique: Des coûts initiaux inférieurs, avecbols vibrants au prix de 18k–40k

| Facteur | électropolissage | Polissage mécanique |

| Travail | Faible (automatisé) | Élevé (manipulation manuelle des supports) |

| Consommables | Électrolyte (50–200/L) | Médias abrasifs (5–20/kg) |

| Énergie | 10–30 kWh/lot | 5 à 15 kWh/lot |

l électropolissage: Réalisesurfaces de qualité stérile avec Ra < 0,3 μm, essentiel pour le contrôle des infections

l Polissage mécanique:Rentable pour les prototypes mais peut nécessiter un nettoyage post-traitement

l électropolissage: Supprimemicro-bavures grâce à la découpe au laser, prévenant la thrombose

l Polissage mécanique

électropolissage excelle dansapplications de haute précision commestents vasculaires, où l’intégrité de la surface n’est pas négociable.Polissage vibratoire mécanique costumesprojets sensibles aux coûts avec des géométries plus simples, telles queprototypes de genoux artificiels. Une approche hybride (par exemple, pré-polissage mécanique + électropolissage) peut optimiser le coût et la qualité pourpinces dentaires

Nous offronsessais de polissage gratuits pour vérifier la qualité de surface avant toute commande groupée. Soumettez vos besoins via notre site web et recevez unrapport personnalisé dans les 12 heures.

E-mail : info@surface-polish.com